Busbar manufacture

At H V Wooding, we specialise in the manufacture of copper and aluminium busbars for use in switchgear components, control panels, panel boards, fuse gear, and transformers.

We produce busbars to specification, down to 0.3mm (copper) and 0.5mm (ali). Our applications range from utilizing polyolefin and PVC for 11KVA switchgear in the energy and rail sectors, to more complex busbars for EV/Hybrid battery systems that are coated with a range of insulation materials, including resicoat HGF03R (red), HFG03R (orange) and Nylon BB, to achieve ratings between 1.5 and 5KV.

As a leading UK manufacturer, our diverse range of manufacturing techniques allows us to produce a wide variety of custom-designed busbars to meet specific requirements. This includes large-scale projects involving thousands of variants as well as small-scale, single part orders with minimal or no tooling costs.

Our technical team, equipped with state-of-the-art equipment and a customer-focused approach, delivers high-specification products to various industries.

Quality is of paramount importance to us, and as a leading British manufacturer, H V Wooding is fully certified to ISO9001:2015, OHSAS 18001 and 14001:2015. We are also members of the SMMT, the Confederation of British Metal Forming, British Safety Council, and Fit for Nuclear.”

Copper Busbars

As a premier busbar manufacturer, H V Wooding boasts an array of the most advanced manufacturing equipment, allowing us to achieve exceptional delivery performance. With many years of experience in taking over the production of copper busbars from major OEM’s through component transfer, we are able to offer a highly responsive service, even with tight lead-times, utilizing state-of-the-art EHRT Punching & Forming Machines.

Copper is a widely utilized metal due to its exceptional conductive properties, durability, and flexibility. It is commonly used in construction, power generation, and the fabrication of electrical components, including wiring and laminated busbars.

- Copper is a strong and durable metal known for its excellent conductive properties and its ability to withstand short circuit electrical currents and high thermal pressure. It is also a malleable and flexible metal, which makes it easy to work with and shape into various forms. Additionally, copper has good resistance to environmental factors such as air, salt, and water, making it one of the most durable and mechanically robust metals available.

- In comparison to other metals, copper is creep-resistant and does not deform or dent under constant stress, making it a safer option for electrical manufacturing. It also has a high resistance to fatigue failure, which is when constant vibrations during the manufacturing process can cause scratches and dents on the surface of the metal.

- Due to its high electrical conductivity, copper effectively carries heat, which reduces energy loss and cuts down on carbon emissions and costs. Additionally, its excellent thermal conductivity and heat transfer properties make it a popular choice for solar water heating and air conditioning systems.

- Copper is 100% recyclable and can be used repeatedly without losing its quality or integrity. It is also a compact and thin metal, which saves space and reduces material wastage and production costs. Copper’s durability and superior performance make it a cost-effective metal for precision engineering components.

For more information on our Copper busbars please click here.

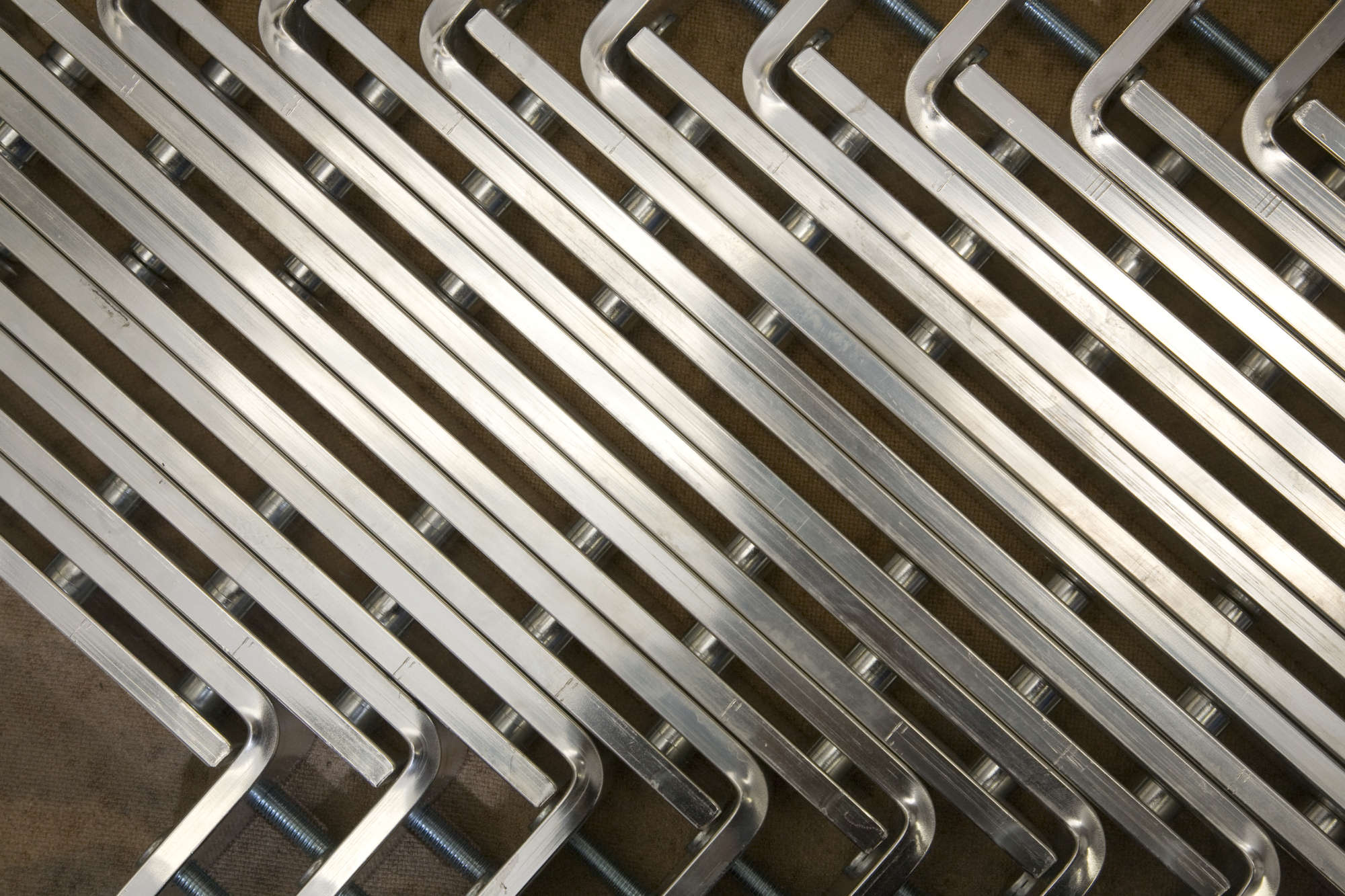

Aluminium Busbars

aluminium is a popular choice for busbar production where weight is a key consideration. At H V Wooding, we have extensive experience in fabricating millions of aluminium busbars for a wide range of industries, including power conversion, rail, marine, and aerospace.

Our aluminium busbars are suitable for use in transformers and are commonly produced for electrical panel boards and distribution boards.

For more information on aluminium busbars please click here.

Flexible Busbars

Flexible Busbars are manufactured using a proprietary endless loop system, providing several technical advantages over other forms of flexible bars in terms of capability and performance. They are constructed from thin, typically soft copper, which is wound and compressed to achieve the necessary cross-sectional area to carry the desired current.

Value Added Busbar services

In addition to our in-house production capabilities, we also offer busbar assembly services. Our services for insulated busbars include powder coating, epoxy coating, heat shrink sleeving, and electroplating in tin, silver, and nickel to meet your specific requirements.

Our applications range from utilizing polyolefin and PVC for 11KVA switchgear in the energy and rail sectors, to more complex busbars for EV/Hybrid battery systems that are coated with a range of insulation materials, including resicoat EL HGC20R and Nylon BB, to achieve ratings between 1.5 and 5KV.

Find out more:

To explore how we could make a difference to your organisation, contact us for a free assessment of potential opportunities.