Electric Motors

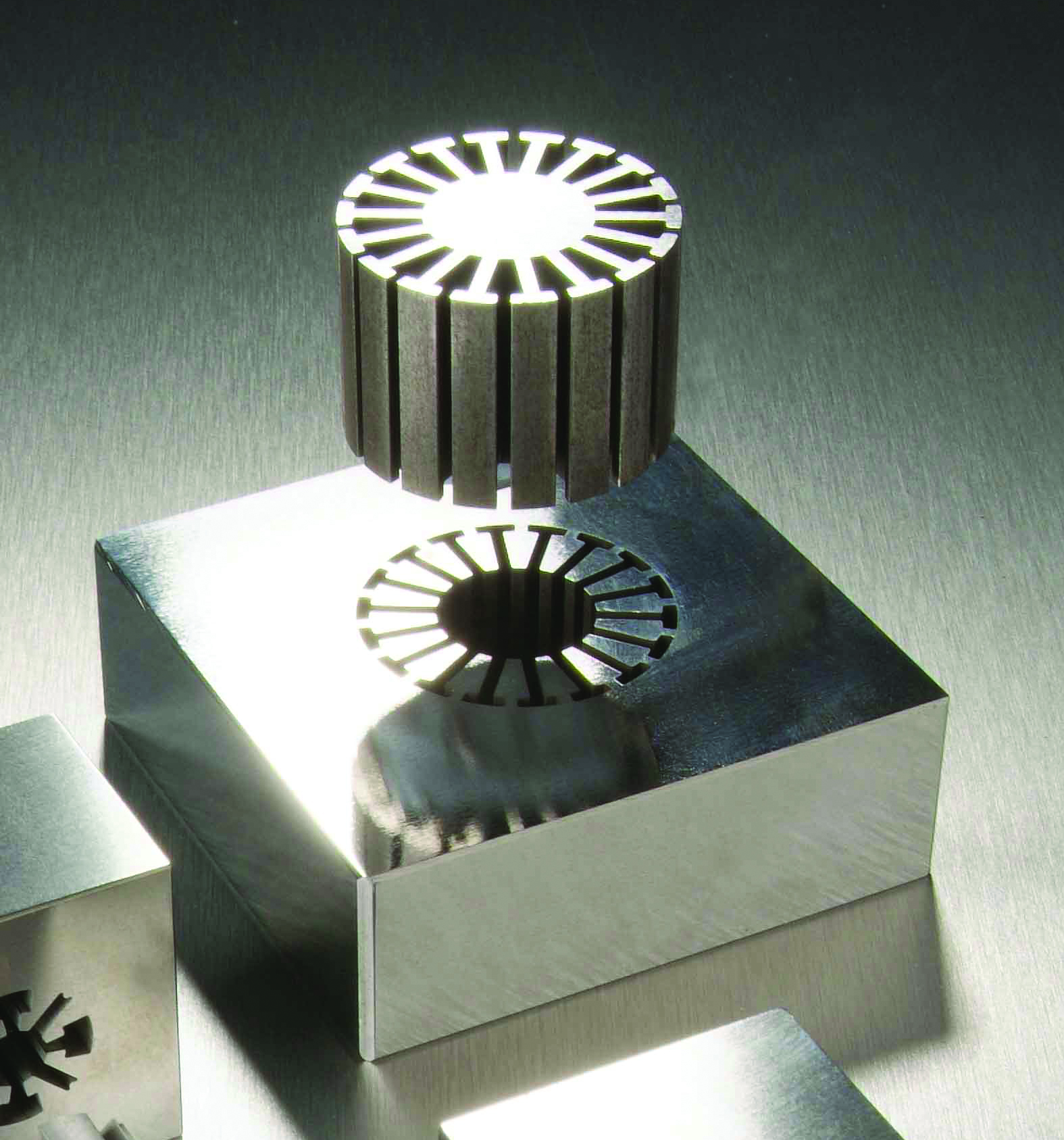

H V Wooding are leading manufacturers of Motor Laminations, core pack assemblies and bonded stacks supported by nearly 40 years of wire erosion services.

Adding value to our customers by optimising the design and manufacturing of complex Motor Laminations and Core Packs, utilising state of the art processes we are able to achieve the most demanding tolerances in a range of Silicon Steels and Cobalt materials.

HV Wooding has been supporting this sector for nearly 40 years by offering Motor Lamination production using Wire EDM, Laser Cutting and Stamping Technologies.

Our core activity in this arena is focused around demanding and complex high end motor applications where we are able to offer customers years of experience in working with a wide range of materials and complex geometries to achieve the demands of the new generation industries.

Find out more:

To explore how we could make a difference to your organisation, contact us for a free assessment of potential opportunities.