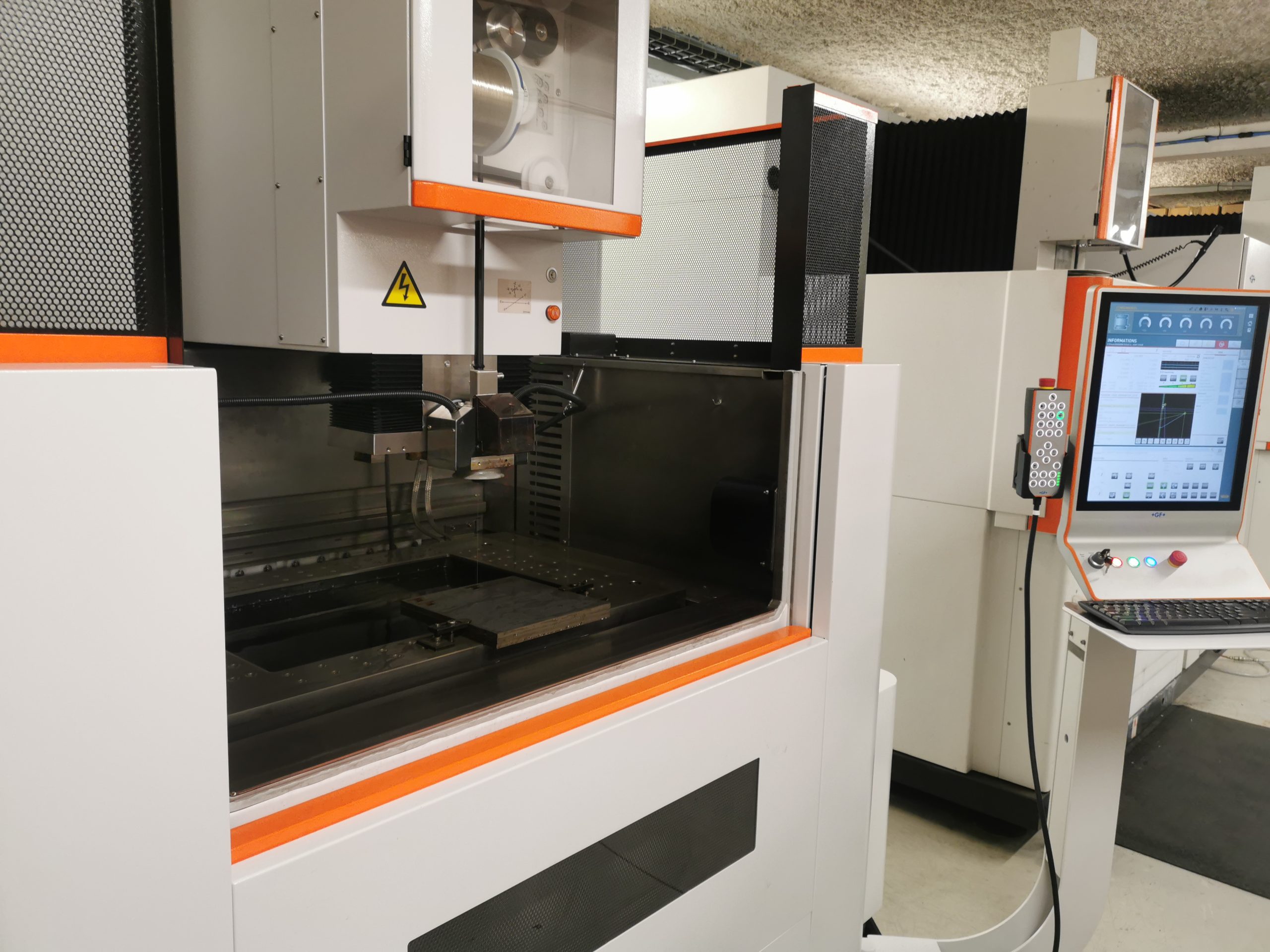

New AgieCharmilles Cut E 600 Wire Erosion Machine

H V Wooding have acquired the AgieCharmilles Cut E 600 Wire Erosion Machine. This state-of-the-art machine utilizes the latest technology to deliver highly precise and accurate results in metal cutting and shaping, making it an ideal addition to H V Wooding’s existing manufacturing capabilities.

The AgieCharmilles Cut E 600 Wire Erosion Machine is an advanced tool that will enable H V Wooding to provide customers with faster turnaround times and greater accuracy in the manufacture of components for various industries, including aerospace, automotive, and medical. The machine’s precision and accuracy in cutting and shaping metal allow for the creation of intricate and complex geometries with tight tolerances, which is essential for the production of bonded stacks.

Bonded stacks are multi-layered components that are widely used in various industries, including aerospace, defense, and automotive. The AgieCharmilles Cut E 600 Wire Erosion Machine’s advanced capabilities in metal cutting and shaping make it an ideal tool for the manufacture of bonded stacks. With the machine, H V Wooding can produce bonded stacks with greater accuracy, repeatability, and consistency, reducing the risk of errors and the need for rework.

The machine’s high-performance and advanced features also enable faster turnaround times, increasing production efficiency and throughput. Additionally, the machine’s ability to cut a wide range of materials, including metals, alloys, and composites, provides greater flexibility in the production of bonded stacks, allowing H V Wooding to meet diverse customer requirements.

“We are excited to add this cutting-edge machine to our manufacturing capabilities,” said Matt Lacey, Sales Manager at H V Wooding. “The AgieCharmilles Cut E 600 Wire Erosion Machine will enhance our precision engineering services and enable us to produce highly complex and intricate parts with greater accuracy and speed, particularly in the manufacture of bonded stacks. The new machine can achieve +/- 5 microns – and this can be improved further using multiple cuts. It is a significant investment for us, and we believe it will add value to our service offering and help us maintain our competitive edge.”

The acquisition of the AgieCharmilles Cut E 600 Wire Erosion Machine demonstrates H V Wooding’s commitment to investing in the latest technology to enhance its manufacturing capabilities and deliver the best possible service to its customers.