Our commitment to Quality

At H V Wooding, quality isn’t just a process — it’s the foundation of everything we do. The precision and accuracy of our components can have critical consequences, from life-saving medical devices to the performance and reliability of renewable energy systems and aerospace applications. For more than 40 years, we’ve been a trusted name in precision manufacturing, consistently delivering excellence to leading clients including Schneider Electric, Honeywell, Rolls-Royce, and GE Renewables.

Accredited and Proven Quality

As a customer-focused manufacturer in a demanding global market, H V Wooding continually invests in innovation and improvement. We are certified to ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018, operating a fully integrated management system that ensures every component meets the highest standards of safety, reliability, and compliance.

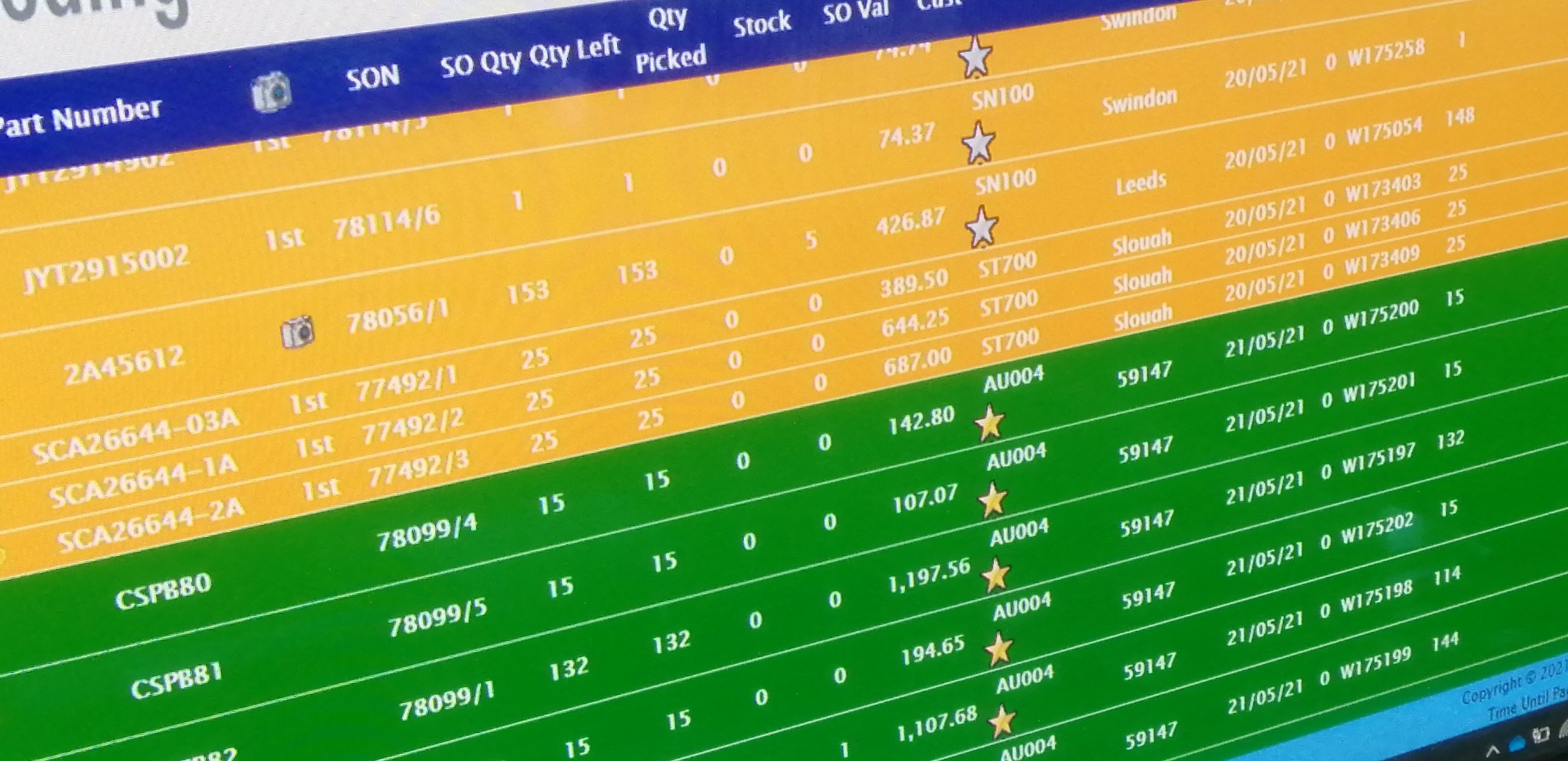

Advanced Quality Systems

Our in-house Buffer Management System and Shop Floor Data Capture System provide live, real-time visibility across the entire manufacturing process. These systems enable precise scheduling, accurate lead-time forecasting, and immediate progress updates, allowing us to communicate the exact status of every customer order. Combined with the principles of the Theory of Constraints, this data-driven approach identifies and removes production bottlenecks, maintaining exceptional on-time, in-full performance and continually improving delivery reliability.

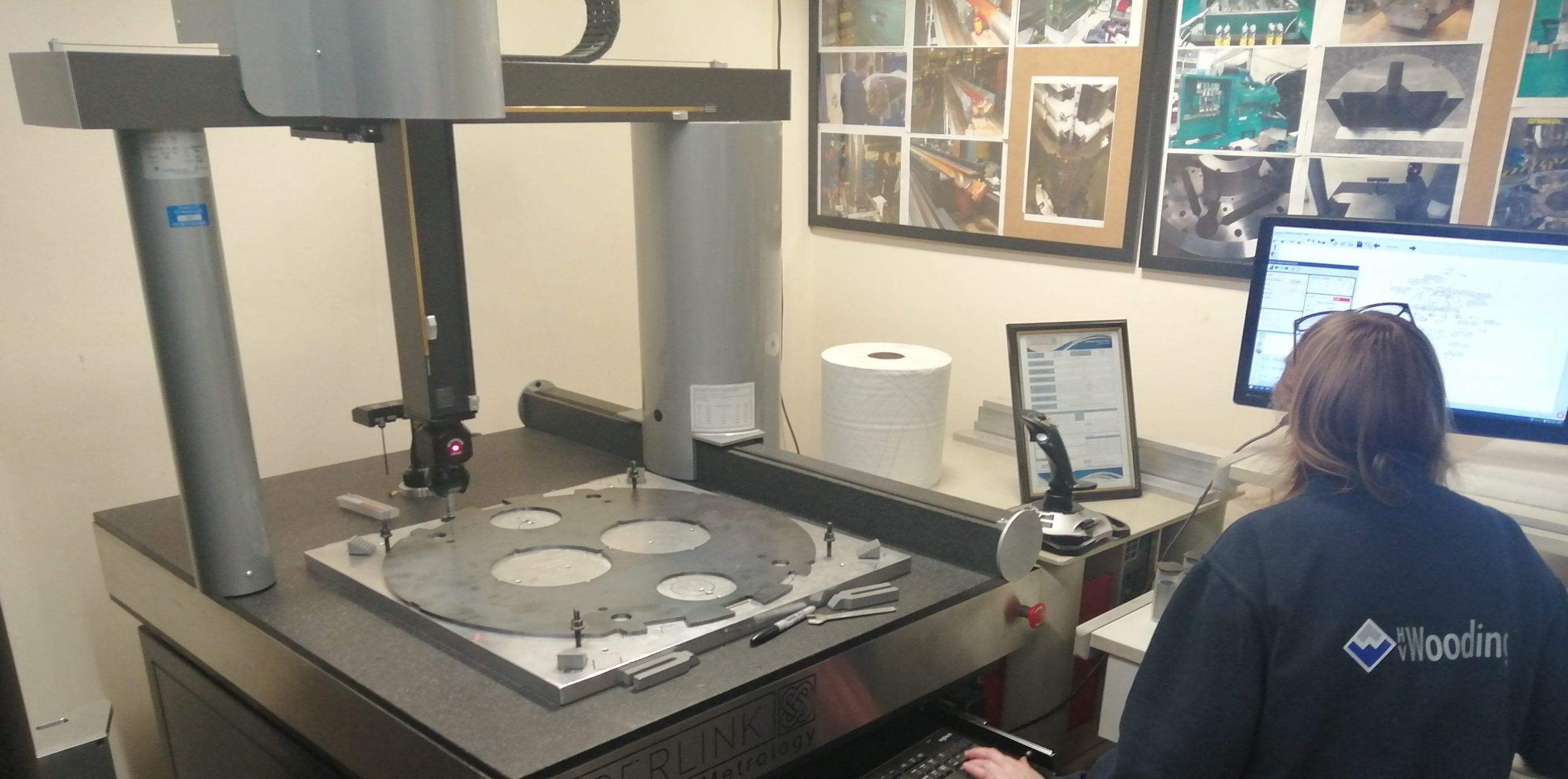

Precision Metrology and Process Control

Quality is measured and verified at every stage of production. Our state-of-the-art metrology department houses advanced CNC coordinate-measuring machines and computerised SPC equipment to guarantee repeatable accuracy. We apply LEAN manufacturing, FMEA, and PPAP methodologies to drive sustainable improvement throughout our operations, ensuring consistent component quality from prototype through to full-scale production.

The Quality Lifecycle

Every project begins with a detailed enquiry process. Our experienced Sales team assess each enquiry against capability, capacity, and specification to confirm feasibility and provide a prompt, competitive quotation.

Once a purchase order is received, it undergoes a structured, cross-departmental contract review involving Sales, Technical, Quality, and Production. The Sales team confirm contractual obligations and documentation requirements. The Technical team analyse drawings and specifications to verify manufacturability, identifying any tooling, materials, or special processes required. Quality specialists review tolerances, inspection methods, and all associated documentation, ensuring compliance with standards such as PPAP and AQL. Production then evaluates scheduling and resources to align manufacturing plans with agreed delivery dates. This thorough review ensures every project begins with complete alignment, traceability, and confidence in compliance.

When the review is complete and materials are available, production begins under carefully controlled conditions. At each stage, a “first-off” component is produced and peer-checked before submission to Quality Control. Only when the component meets all specified requirements does batch production commence. Throughout manufacturing, inspections follow documented control plans incorporating ISIR or PPAP where required, guaranteeing conformity at every step.

After all operations are complete, products undergo final inspection by the Quality Control department before despatch. Items are securely packaged to customer specifications or HV Wooding standards, with photographic records taken before shipment. Certificates of Conformity are provided when requested. This rigorous approach ensures products arrive in perfect condition and ready for immediate use.

Our responsibility to quality continues beyond delivery. We actively seek feedback from every customer to measure satisfaction and identify areas for enhancement. This dialogue strengthens relationships and supports continuous improvement, ensuring H V Wooding consistently surpasses expectations and maintains its position as one of the UK’s most trusted precision manufacturers.

Accreditations and Memberships

Our Integrated Management System combines all ISO certifications with customer-specific audits and approvals. This ensures flexibility, traceability, and full compliance across a diverse range of industries, including medical, renewable energy, motorsport, and aerospace.

Customer Feedback

Our Vision: To be the UK’s most trusted precision manufacturer, delivering innovation, quality, and reliability across every component we produce.

Our Mission: To exceed customer expectations through engineering excellence, continuous improvement, and a commitment to quality in every project, from concept to delivery.

Did we get it right? Please contact our team on 01303 264471.