Motor Laminations and Core Packs

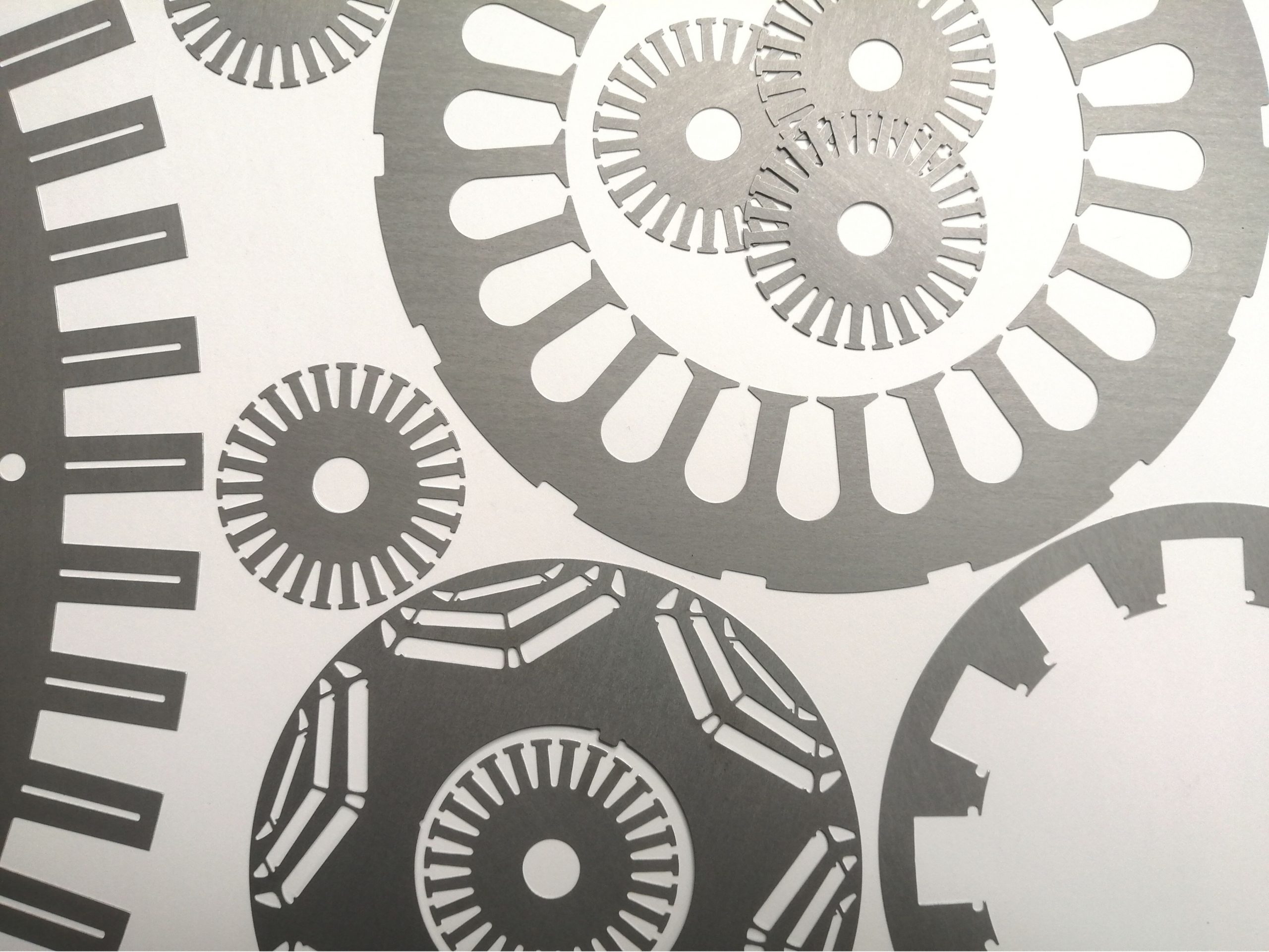

At H V Wooding, we add value to every project by optimising the design and manufacture of complex motor laminations and core packs. Using state-of-the-art production processes, we achieve the most demanding tolerances across a wide range of silicon steels and cobalt materials.

For nearly 40 years, we have supported motor lamination projects using wire erosion, laser cutting, and precision stamping technologies. Our laminations are manufactured to customer specifications — supplied loose or bonded — in all grades of electrical steel. We are proud to support high-performance industries such as aerospace, motorsport, defence, and renewable energy, where reliability and precision are critical.

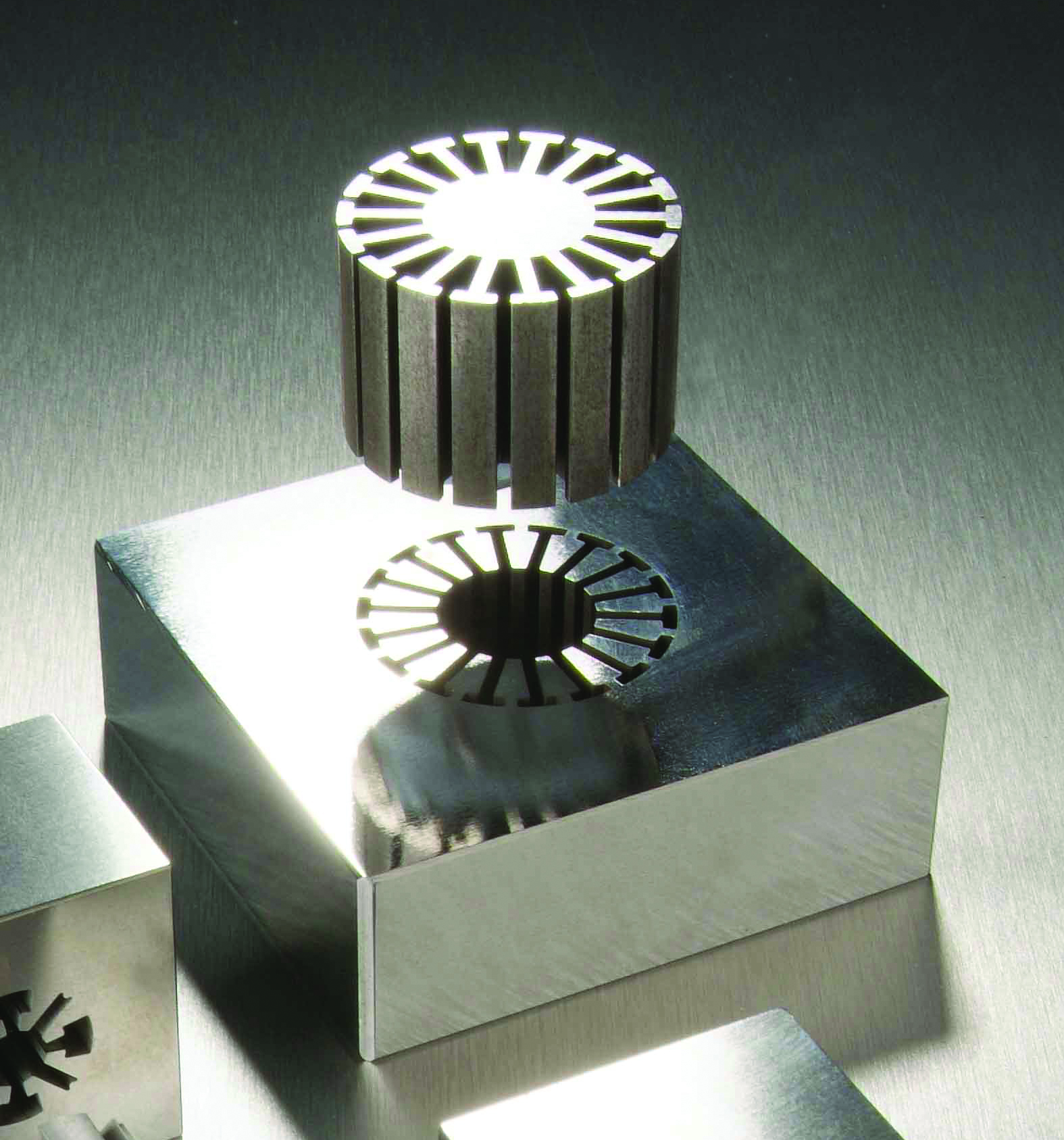

Bonded Lamination Stacks

As leaders in bonded lamination technology, we provide both pre-bonded and post-bonded solutions to meet specific customer requirements. Pre-bonded wire-eroded stacks are frequently used for prototyping and early-stage testing, allowing rapid validation of design concepts. Once approved, we can scale production efficiently using laser cutting or high-speed stamping techniques combined with post-bonding processes to ensure consistency and performance in volume manufacture.

This flexibility allows customers to move seamlessly from prototype to full production while maintaining tight control of tolerances, cost, and turnaround times.

Precision Manufacturing for Advanced Motor Applications

Our core expertise lies in the manufacture of high-end, complex motor laminations for next-generation applications. We combine decades of experience with advanced materials and intricate geometries to deliver exceptional results in performance-critical sectors.

We have refined our manufacturing processes over years of collaboration with customers across aerospace, Formula One, defence, and advanced engineering, ensuring that every component meets the most stringent quality standards.

Our metrology department, equipped with CMM and Quick Scope systems, provides full dimensional verification, while our manufacturing technology — including automatic wire feeding, submerged cutting, and large-format capacity up to 500mm diameter and 200mm depth — guarantees precision and repeatability at every scale of production.

Materials and Tolerances

We work with electrical steels ranging from 0.1mm to 1.0mm thickness, including silicon and cobalt iron grades and pre-glued materials such as Suralac 9000. Our manufacturing processes achieve tolerances as tight as ±5 microns, delivering the accuracy demanded by high-performance electrical machines.

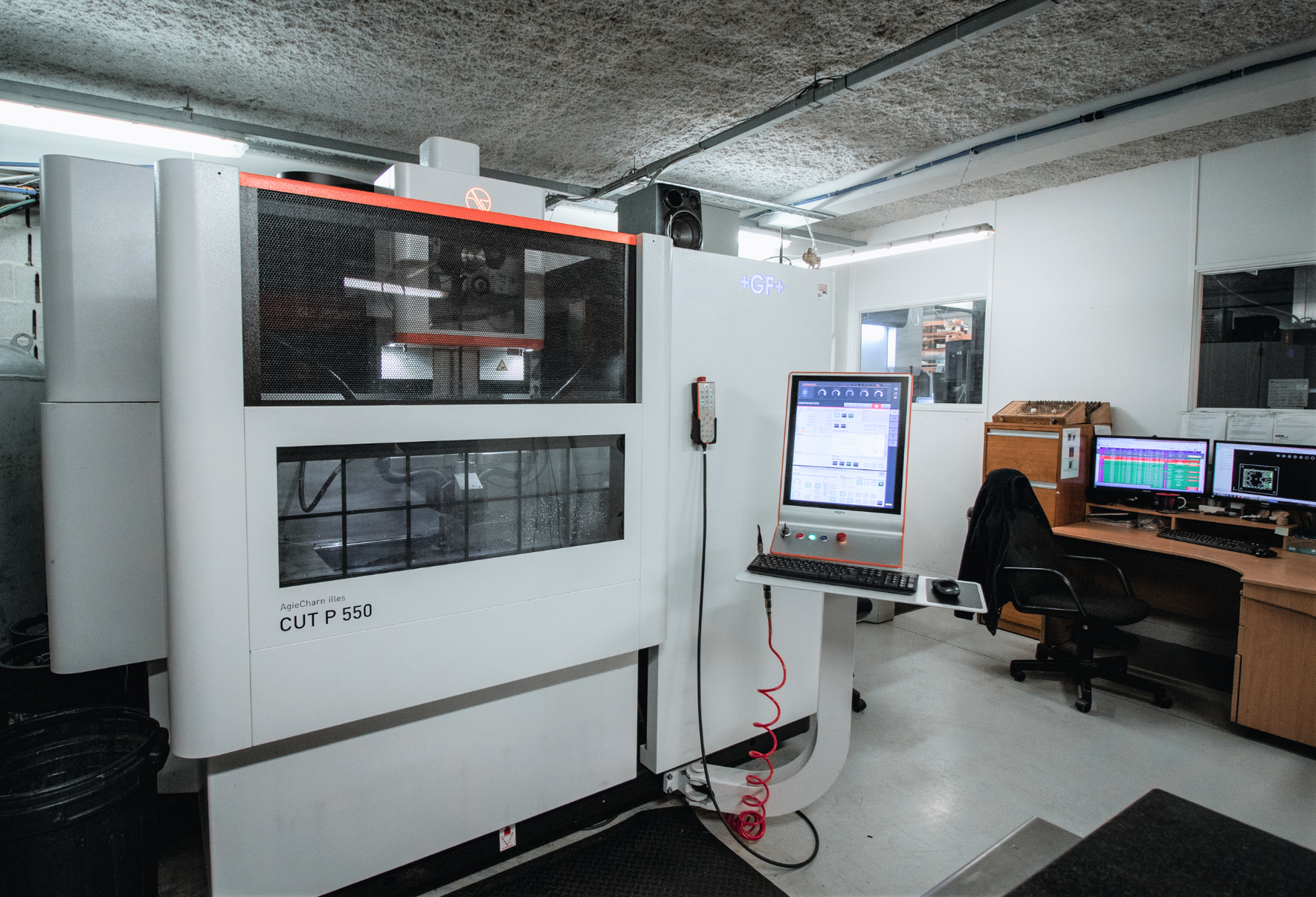

Investment in Technology

To maintain our position at the forefront of precision manufacturing, H V Wooding continuously invests in the latest technology. Our recent investment of over £500,000 in a Trumpf TruLaser 3030 and a high-speed press further enhances our production capacity and reduces lead times.

These advancements allow us to deliver faster turnaround, greater consistency, and increased flexibility for both prototype and volume production projects.

Partnering for Success

Whether you need prototype laminations, volume core packs, or technical advice on material selection and bonding methods, our experienced engineers are here to help. We provide a complete end-to-end service — from concept and testing to full production and inspection — supported by our Quality systems and decades of engineering experience.

Discover more about our recent projects on our Case Studies page.