Genset & CHP

H V Wooding manufactures high-performance Genset & CHP busbars for generator OEMs and power-system integrators. We deliver precision-engineered copper and aluminium busbars designed for reliability, thermal performance and long-term durability in demanding generator and combined heat & power applications.

Precision Busbars for Generator & CHP Systems

H V Wooding manufactures high-performance busbars for Genset and CHP applications, supporting OEMs producing diesel generators, gas gensets and combined heat and power units. Our busbars are engineered for reliability, thermal efficiency and long-term durability in demanding power-generation environments. Operating under ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018, we deliver consistent quality across prototypes, pre-production runs and mid-volume manufacturing.

Why Use Busbars in Genset & CHP Systems?

Reliable busbars are critical to the safe and efficient operation of generator and CHP equipment. They provide high current-carrying capability, maintain excellent thermal stability even under heavy or fluctuating loads, and offer superior vibration resistance compared with traditional cabling. Their compact, space-efficient form helps simplify internal layouts within generator enclosures while also reducing installation time. These characteristics make busbars the preferred choice for designers and manufacturers seeking long-term reliability in both standby and continuous-duty power systems.

Custom Busbar Manufacturing Capabilities

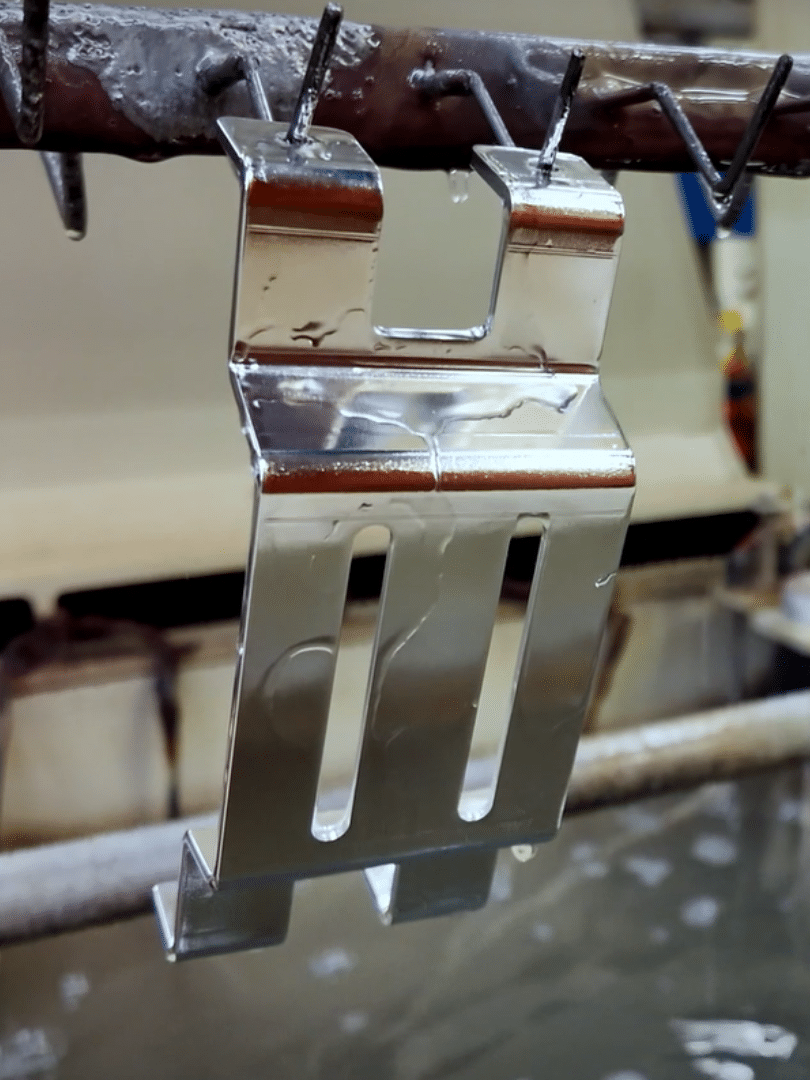

H V Wooding produces copper and aluminium busbars for generator and CHP systems using advanced laser cutting, CNC machining, wire erosion and precision forming technologies. This allows us to create everything from simple flat conductors to complex multi-bend components for alternator, switchgear and distribution connections. We also manufacture flexible and laminated busbars for vibration-sensitive generator environments, and we routinely incorporate machined features such as slots, terminals, and precision-positioned fixings. Our ability to supply fully assembled busbar kits helps streamline customer production and installation processes.

Insulated & Coated Busbars

To ensure performance in harsh Genset and CHP environments, we offer a complete range of insulation and protective coatings. Epoxy powder coating and heat-shrink insulation provide enhanced resistance to heat, moisture and vibration. These finishing options are applied in-house to maintain full quality control.

Prototype to Mid-Volume Production

We support generator and CHP manufacturers at every stage of product development. Our rapid prototyping service allows customers to validate designs at speed, while our flexible production capability enables smooth progression into small batches or mid-volume runs. Throughout, our focus remains on precision, consistency and dependable lead times.

Typical Genset & CHP Applications

Our busbars are used in diesel generator sets, gas engine generators, combined heat and power units, micro-CHP systems, containerised generator modules and industrial or commercial power packages. They are also widely applied in data-centre backup systems where reliability under high load and variable duty cycles is essential. Power-generation OEMs rely on our accuracy to ensure stable electrical performance throughout the lifespan of their equipment.

Why Choose H V Wooding?

Customers choose H V Wooding for our combination of precision engineering, in-house capability and proven performance in demanding applications. Our manufacturing processes achieve tight tolerances, supported by the same laser, wire-erosion and CNC technologies trusted on globally significant engineering projects, including components supplied for CERN. Because every stage of production takes place under one roof, we maintain full control of material traceability, quality assurance and delivery timelines. Our busbars are designed to withstand the heat, vibration and environmental challenges found in generator housings, and our optimised workflows support both rapid prototyping and efficient scaling into production. All work is carried out under our ISO-certified management systems.

Supporting OEMs in Power Generation

Our engineering team works closely with generator and CHP manufacturers to optimise conductor designs, enhance electrical and thermal performance, reduce material usage and simplify installation through modular busbar solutions. We routinely produce complex geometries and high-current components that meet the demands of modern power-generation systems. This collaborative approach enables shorter development cycles, improved reliability and more efficient production for our customers.

Speak to Our Team

Whether you are developing a new Genset or CHP system or seeking to improve an existing design, our engineers are ready to help. We can provide rapid quotations, design support and production-ready busbar manufacturing tailored to the needs of generator and CHP applications.